Sustainability and Savings: How Robopac Pallet Wrapping Machines Contribute to Eco-Friendly Packaging

In an era where environmental consciousness is paramount, businesses are seeking innovative ways to integrate sustainability into their operations. The world of packaging has not been left untouched by this trend, with the emergence of Robopac Pallet Wrapping Machines as a game-changer in the field. This blog delves into how these cutting-edge machines contribute to both eco-friendly packaging practices and cost savings. Additionally, we'll highlight the expertise of Compak, a trusted name that offers a range of packaging solutions, including the remarkable Robopac Pallet Wrapping Machine.

Packaging and Sustainability: An Essential Connection

Packaging plays

a pivotal role in the quest for sustainability. Businesses are increasingly

recognizing that packaging choices can significantly impact their carbon

footprint, waste generation, and overall environmental impact. As a result,

innovative solutions that balance sustainability and efficiency are highly

sought after.

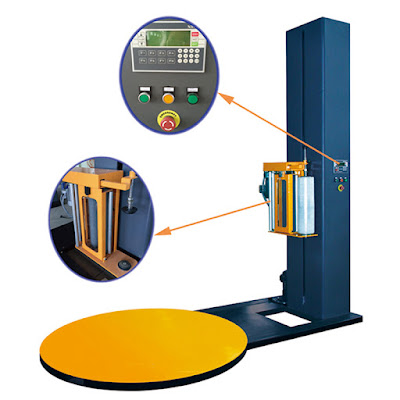

The Revolution of Robopac Pallet Wrapping Machines

Robopac Pallet Wrapping Machines are transforming the landscape of packaging with their eco-friendly and efficient features:

Film Optimization: These machines are equipped with advanced

technology that optimizes the use of stretch film, minimizing material wastage

while ensuring secure packaging.

Energy Efficiency: Robopac machines are designed to operate with

minimal energy consumption, contributing to reduced carbon emissions and lower

operational costs.

Stability and Protection: Properly wrapped pallets reduce the risk of

product damage during transit, eliminating the need for excessive packaging

materials.

Cost Savings through Efficiency

The allure of Robopac machines extends beyond sustainability; they also deliver substantial cost savings:

Reduced Labor Costs: Automated wrapping eliminates the need for

manual labor, allowing employees to focus on more value-added tasks.

Consistency and Accuracy: Automated wrapping ensures consistent tension

and film application, reducing errors and potential damages.

Time Efficiency: These machines work swiftly, contributing to

faster packaging processes and increased throughput.

Compak's Expertise with Robopac

Compak, a prominent player in the packaging industry, brings the benefits of Robopac Pallet Wrapping Machines to businesses seeking both sustainability and efficiency:

Innovative Solutions: Compak's commitment to staying at the

forefront of packaging technology is evident through their offerings, including

the advanced Robopac machines.

Customization: Understanding that each business has unique requirements, Compak

offers tailored solutions to align with specific production needs.

Expert Consultation: Compak's experienced team provides expert

guidance, helping clients select the most suitable packaging solutions for

their operations.

Final Thoughts: Embracing Sustainability with Compak and Robopac

The union of

sustainability and efficiency is a hallmark of progress in today's business

landscape. Robopac Pallet

Wrapping Machines, championed by Compak, exemplify this harmony,

offering an array of benefits that resonate with businesses of all sizes. When

businesses opt for Robopac solutions, they're making a conscious choice to

reduce their ecological impact, optimize operational efficiency, and contribute

to a more sustainable future. Compak acts as a trusted partner in this journey,

ensuring that clients receive packaging solutions that meet their unique needs

while aligning with their commitment to sustainability. In conclusion, the

adoption of Robopac Pallet Wrapping Machines represents a significant step

forward for businesses seeking a greener and more efficient approach to

packaging. As demonstrated by Compak's expertise, these machines not only

reduce waste and energy consumption but also offer cost savings and operational

enhancements. By embracing Robopac, businesses are not just investing in

machinery; they're investing in a sustainable future where innovation and

responsibility coexist harmoniously.

Comments

Post a Comment