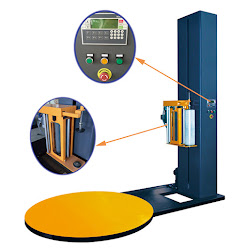

Pallet Wrapping Machine is a highly automated equipment to load and unload. Pallets are stacked with goods inside the pallet wrapper, they can quickly change the shape of things, so that different products from one pallet, which makes it more efficient logistics process has been developed.

In

order to enhance this efficiency of companies have emerged before the wrap

machine. This Pallet Wrapper is installed on the pallets of goods, while some

are placed on top of the table wrapped in stretch film or plastic sheeting to

form a square box with the goods inside, so that it can be lifted more easily ,

can maintain its balance during transportation.

Structural

features for this equipment are quite complex, the structure of this equipment

is very sophisticated. Parts are joined by welding or fasteners to dismantle

the equipment is not easy, just like a car engine units are disassembled increasingly

complicated.

Pallet

Wrapping Machine for sale

This

Pallet Wrapping Machine

working principle is very simple, after installation on top of the table loaded

with goods, the bottom of the table is fixed with belts, after that by changing

system control panels for automatically wrapping stretch film or plastic

sheeting to form a square box with goods inside.

Therefore,

this equipment can be called fully automated production line, not only need to

wait for human operation, but also easy to take over. During transportation

process were reduced to a minimum, so that the machine can be controlled by a

single person, but also can save manpower.

In

order to reduce breakdowns in transportation process, the Pallet Wrapper is

fully enclosed design structure with good sealing property. In addition it also

has dust proof and waterproof function. In this way, you can ensure product

quality even banged for a long time in transport.

Therefore,

the Pallet Wrapper not only can solve problems fixed packaging pallets, but

also can help you save money, reduce high labour costs and maintain product

quality during transportation process.

Pallet

Wrapping Machine Advantages

1.

Saving manpower - the whole automatic production line,

only need to conveyor belt running operation control box can be automated

packaging process. So no workers in human factors, but also efficient work

2.

Save costs - with low labour costs, equipment easy

to use

3.

Product quality - during transportation process, no

broken product can ensure the quality of goods

4.

Productivity - more efficient packing process,

shortens the time between loading and unloading goods.

Original Source Content -

5.

Flexibility - Pallet Wrapper designed for standard

pallets, can be easily replaced and changed into different sizes and shapes

6.

Easy maintenance - the machine is designed to be easy to

maintain, replace parts easy handling.

Original Source Content -

Comments

Post a Comment