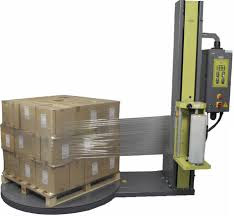

Pallet wrapping is one

of the essential needs of the packaging world. It is no less than a scientific

discovery. One of the good things about pallet wrapping as it aims to minimize

the vital aspects of packaging material which makes all the difference. This is

needed to protect the workforce and make a significant change. It helps people to

concentrate on things and other activities in the nick of time. That's the

reason why Pallet Wrap Machine

provides efficient and quality services which is important.

The

Evolution of Pallets In the market...

It is surprising to see

how far the technology has grown in the last few years. The beginning of delivering

goods and products on pallets began in the late 60s when the supermarkets gained

popularity over local shops. Rather than delivering to small shopkeepers, the

producers started delivering their products to distribution warehouses and hence

the need for pallets came into existence. During the early 1970s, with the

growing demand for pallets, manufacturers realized the need to wrap loads with

something which provides load stability and prevention of this.

The ease of applying

stretch film resulted in its adoption in many industries. That was in huge

demand globally. Before being used as a pallet wrap, it was used in many different

applications. PVC based film came out to

be the captivating options for pallet wrap, due to its capability. So, why not

fulfil the requirement for an efficient resource.

Benefits- Pallet Wrapping machine helps in enhancing the

efficiency of packaging. It can also raise the productivity which saves cost; money

ad prevents the good from dust, water and pollutants. These machines are tested

on varied parameters which ensure flawlessness. For some reasons, Compak is one

of the leading suppliers in the market with the potential to raise business volumes.

Original

Source Content:-

https://compak.wordpress.com/2019/07/06/how-pallet-wrapping-have-transformed-packaging-industry/

Comments

Post a Comment